DIC is a leading Manufacturer of all kinds of PCD, CBN Tools based in India, widely used in automobile industries for various applications. DIC has various PCD tools which include reamers, drills, end mill inserts, etc. We have also available in any customized sizes as per customer requirements. PCD Reamers: mainly used in many automobiles industry and engineering industries for the machining of aluminum and other non-ferrous metals. CBN TOOLS: Used for machining hardened steel because it provides a cost-effective alternative to grinding processes. CVD TOOLS used to deposit conformal films and augment substrate surfaces. Products made using high-quality raw materials. Also available as per customer drawings or samples.

Difference between PCD and CBN: The advantage of PCD is primarily its constantly high quality – a foundational precondition for the further machining of tools with the same characteristic. CBN End Mills is a high-performance tool material from a polycrystalline mass. Example: PCD is produced in a high temperature-force process.

High Speed Performance: These can run up to 10 times faster than solid carbide tools at their peak efficiency and effectiveness. That means that jobs are finalized faster and increase the amount of work that can be completed.

Customer Satisfaction: We are a PCD, CBN, and CVD cutting tools manufacturer. DIC’s highly experienced team is behind the success of our company. We never compromised with the quality of the products. DIC TOOLS believes in building long-time relations with our recognized clients. PCD alone can create a faster, more streamlined process, saving time and money.

Surface Finish: Our PCD tools can deliver a high-quality surface finish except for the need for a secondary operation. That means DIC Tools can save time and money while maintaining a high-quality standard.

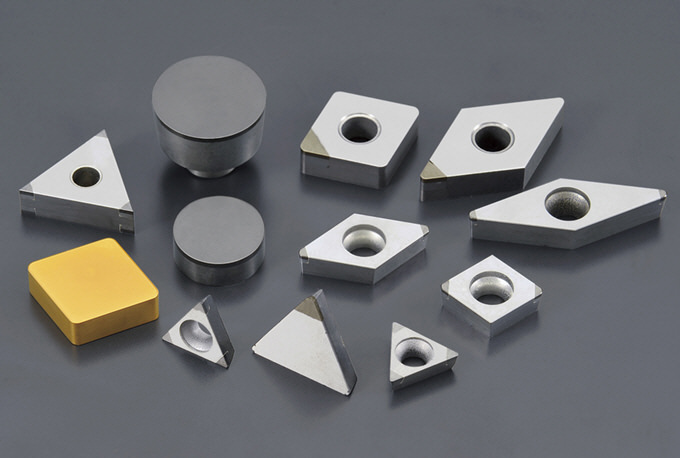

Below are some types of PCD, CBN, and CBD Tools:

PCD/CBN Reamers: We are a PCD and CBN Tools Manufacturer based in India. Used in automobile industries for machining almost all their non-ferrous parts, for example: engines, transmissions, wheels, etc. Our PCD Tools delivers excellent performance results when reaming non-ferrous metals. Also run at a higher speed than the carbide. Specifically made to machine aluminium. Our reamers provide compatible results for a longer time than their traditional counterparts. These are especially suitable for drilling, milling, and reaming of non-ferrous materials. Reaming with a PCD tool allows the user to ream holes faster, to tighter tolerances, and produce cleaner-edge holes. These Reamers usually run at 8000-12000 rps although carbide reamer runs at 2500 rpm. Running Speed: 8000- 12000 rpm approximate.

CBN End Mills: CBN (Cubic Boron Nitride) End Mills. These are suitable for milling hard hardened steel as compared to solid carbide end mills. The CBN end mills are very standard in their operations. These are efficient in work. It is the second strongest End mill. Suitable for both manned and unmanned milling of steel due. Our CBN End Mills have also featured high precision, a long life span, low prices, and a facility of regrinding service. End mills can be reground multiple times. This is available in diameter ranging from 0.1 mm to 6mm, and applicable for steel up to 70 HRC. DIC is a reliable supplier of CBN end mills. Milling Temperature up to 1200 °C.

PCD Drills: PCD Drills (Polycrystalline Diamond). DIC is a PCD Manufacturer based in India. Our Drills are multi-application and high-performance drills that provide high capacity utilization, flexibility, and adjustability. These are the hardest and more resistant to abrasion than the traditional carbide tooling. Designed for use on composite material. Recommended for use with aluminium alloys, matrix composite and plastic materials. DIC is a reliable supplier of PCD Drills, made from high-quality raw material. These are available in diameters ranging from 1.5 mm to 19 mm. Multi-steps and are made to custom length and diameters also available. Milling Temperature: 1200°C.

PCD Inserts: PCD Inserts (Polycrystalline Diamond). These are suitable for non-ferrous metals, milling, and other types of cutting. Our PCD Inserts ensure longer tool life due to high hardness and stable machining. Due to this reason, you can machine at high cutting speed. PCD Inserts from DIC Tools having Excellent Wear Resistance, Outstanding Cutting Performance. Provide faster machining times compared to grinding and are suited to outperform ceramics-based solutions. We also have PCD Inserts available as per customer drawings or samples. The inserts decrease the build-up edge and allow high precision machining. DIC is a reliable supplier of PCD Inserts. Our products are made using high-quality raw materials.